cpm award

Back to ArchivesConstruction Excellence Recognized with 2006 ACM Build Maine Award

|

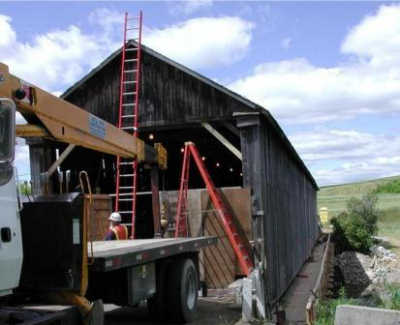

Photo courtesy CPM |

|

Photo provided by ACM. |

AUGUSTA, Maine, May 16, 2006 -- CPM Constructors has been recognized for project excellence with a 2006 Build Maine Award from Associated Constructors of Maine, Inc. The Freeport-based general contracting firm was honored in the Specialty Contractor category for restoring the Watson Settlement Bridge, a historic covered bridge located in Littleton, Maine.

According to CPM, the bridge was out of plumb, out of square and skewed, making its rehabilitation anything but run-of-the-mill. To successfully complete this project, the construction team replaced decayed wooden members throughout the structure and nearly 60% of the roof. In fact the crew essentially rebuilt the bridge as it had been constructed nearly a century ago: by bolting all members into place. The award-winning craftsmen also used many of the same tools and techniques employed by the bridge's original constructors. Additionally, every effort was made to replace the old or damaged lumber with the same species of wood, requiring considerable research and communication with wood mills in Maine, New Hampshire, Vermont, and Canada.

During the course of this project, workers constantly faced challenges in holding the bridge together and keeping it square as old portions of the bridge were removed and new structural members were added. To overcome this obstacle, the crew devised a plan to support the bridge using come-a-longs and a jacking system that worked off of four-inch spanning steel beams which were put under the bridge earlier as a temporary repair. On any given day, it wasn't unusual to see 15 come-a-longs in place, which the crew would monitor and adjust depending on where work was being performed or what type of work was being completed.

Pursuant to the $800,000 contract and specifications, CPM Constructors had to straighten and complete the bridge renovation without using any additional wood members. However, the temporary steel beams that ran along the bottom of the bridge also had to be removed. The come-a-longs and jacking method enabled the crew to systematically replace old wood members with the same number of new wood members while removing the steel beams.

Another challenge involved adjustments in the bridge brought about by atmospheric changes. Since much of the covered bridge was a crisscross structure, changes in weather, temperature, or humidity caused the distance between the base of the bridge and peak of the roof to vary by as much as six inches as the bridge retracted or expanded. Without careful thought and measurements, new pieces cut and put together from something removed in the morning might not fit in the afternoon, due to the bridge having retracted and the distance between the base and the roof having increased. As the CPM team became more familiar with the bridge and these atmospheric impacts, the challenge abated.

Environmental concerns posed yet another test as the contractor strived to minimize the project's impact on the river below. Once again, the come-a-longs and jacking system proved invaluable, precluding the need to place any temporary support structures in the river to hold the bridge during construction. Additionally, using sand bags and concrete barriers, the crew built a cofferdam that ran from the riverbank to the center pier. The cofferdam was wide enough to allow an excavator traveling on crane mats to do the necessary excavation and repair work to the pier, and keep the debris from entering the water. When it came to disposing of the debris removed from around the pier, the contractor was informed that much of the material was unfit to remove from the site due to the natural accumulation of deposits containing mercury. After consulting with the Maine Department of Transportation and giving the issue some thought, the crew placed the debris on the embankments, placed geo-technical material on top of it, and covered it with rip rap, thus keeping the debris in its natural environment and, at the same time, handling the debris in an appropriate manner. Perhaps best of all, the constructor proudly reports that it conquered all of these challenges without logging a single lost-time injury on the project.

The rehabilitation of the Watson Settlement Bridge returned an important Aroostook County structure back to its former self, enabling pedestrian and bike traffic to enjoy the northernmost and last original covered bridge built in Maine. And thanks to CPM's extra care and effort to keep the bridge in its original context, the refurbished structure befits its designation as an American Society of Civil Engineering State Historic Civil Engineering Landmark.

Chartered in 1951, Associated Constructors of Maine is a state chapter of the Associated General Contractors of America and represents the interests of 275 construction firms and related businesses throughout Maine.

[This article forwarded to us for release by Scott Tompkins, Deputy Director, Associated Constructors of Maine. Contact; stompkins@acm-inc.org - Ed.]

Joe Nelson, P.O Box 267, Jericho, VT 05465-0267

This file posted 9:50 AM 5/9/2006

Joe Nelson, P.O Box 267, Jericho, VT 05465-0267

This file posted 9:50 AM 5/9/2006